AWS machine learning supports Scuderia Ferrari HP pit stop analysis

Challenges with pit stop performance analysis Historically, analyzing pit stop performance has required track operations engineers to painstakingly review hours of footage from cameras placed at the front and the rear of the pit, then correlate the video to the car’s telemetry data… For a typ…

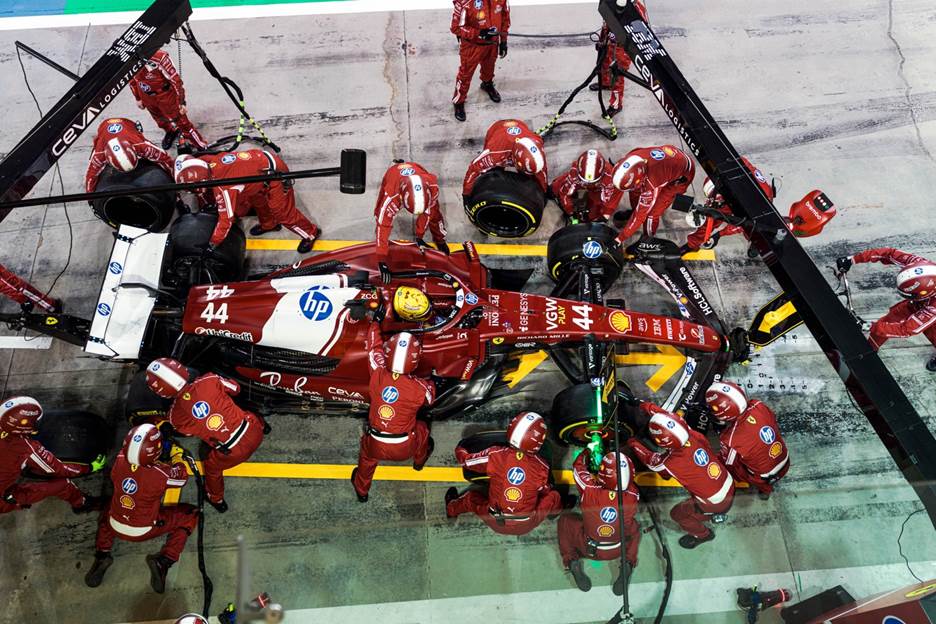

As one of the fastest sports in the world, almost everything is a race in Formula 1® (F1), even the pit stops. F1 drivers need to stop to change tires or make repairs to damage sustained during a race. Each precious tenth of a second the car is in the pit is lost time in the race, which can mean the difference between making the podium or missing out on championship points. Pit crews are trained to operate at optimum efficiency, although measuring their performance has been challenging, until now. In this post, we share how Amazon Web Services (AWS) is helping Scuderia Ferrari HP develop more accurate pit stop analysis techniques using machine learning (ML).

Challenges with pit stop performance analysis

Historically, analyzing pit stop performance has required track operations engineers to painstakingly review hours of footage from cameras placed at the front and the rear of the pit, then correlate the video to the car’s telemetry data. For a typical race weekend, engineers receive an average of 22 videos for 11 pit stops (per driver), amounting to around 600 videos per season. Along with being time-consuming, reviewing footage manually is prone to inaccuracies. Since implementing the solution with AWS, track operations engineers can synchronize the data up to 80% faster than manual methods.

Modernizing through partnership with AWS

The partnership with AWS is helping Scuderia Ferrari HP modernize the challenging process of pit stop analysis, by using the cloud and ML.

“Previously, we had to manually analyze multiple video recordings and telemetry data separately, making it difficult to identify inefficiencies and increasing the risk of missing critical details. With this new approach, we can now automate and centralize the analysis, gaining a clearer and more immediate understanding of every pit stop, helping us detect errors faster and refine our processes.”

– Marco Gaudino, Digital Transformation Racing Application Architect

The solution uses object detection deployed in Amazon SageMaker AI to synchronize video capture with telemetry data from pit crew equipment, and the serverless event-driven architecture optimizes the use of compute infrastructure. Because Formula 1 teams must comply with the strict budget and compute resource caps imposed by the FIA, on-demand AWS services help Scuderia Ferrari HP avoid expensive infrastructure overhead.

Driving innovation together

AWS has been a Scuderia Ferrari HP Team Partner as well as the Scuderia Ferrari HP Official Cloud, Machine Learning Cloud, and Artificial Intelligence Cloud Provider since 2021, partnering to power innovation on and off the track. When it comes to performance racing, AWS and Scuderia Ferrari HP regularly work together to identify areas for improvement and build new solutions. For example, these collaborations have helped reduce vehicle weight using ML by implementing a virtual ground speed sensor, streamlined the power unit assembly process, and accelerated the prototyping of new commercial vehicle designs.

After starting development in late 2023, the pit stop solution was first tested in March 2024 at the Australian Grand Prix. It quickly moved into production at the 2024 Japanese Grand Prix, held April 7, and now provides the Scuderia Ferrari HP team with a competitive edge.

Taking the solution a step further, Scuderia Ferrari HP is already working on a prototype to detect anomalies during pit stops automatically, such as difficulties in lifting the car when the trolley fails to lift, or issues during the installation and removal of tires by the pit crew. It’s also deploying a new, more performant camera setup for the 2025 season, with four cameras shooting 120 frames per second instead of the previous two cameras shooting 25 frames per second.

Developing the ML-powered pit stop analysis solution

The new ML-powered pit stop analysis solution automatically correlates video progression with the associated telemetry data. It uses object detection to identify green lights, then precisely synchronizes the video and telemetry data, so engineers can review the synchronized video through a custom visualization tool. This automatic method is more efficient and more accurate than the previous manual approach. The following image shows the object detection of the green light during a pit stop.

“By systematically reviewing every pit stop, we can identify patterns, detect even the smallest inefficiencies, and refine our processes. Over time, this leads to greater consistency and reliability, reducing the risk of errors that could compromise race results,” says Gaudino.

To develop the pit stop analysis solution, the model was trained using videos from the 2023 racing season and the YOLO v8 algorithm for object identification in SageMaker AI through the PyTorch framework. AWS Lambda and SageMaker AI are the core components of the pit stop analysis solution.

The workflow consists of the following steps:

- When a driver conducts a pit stop, front and rear videos of the stop are automatically pushed to Amazon Simple Storage Service (Amazon S3).

- From there, Amazon EventBridge invokes the entire process through various Lambda functions, triggering video processing through a system of multiple Amazon Simple Queue Service (Amazon SQS) queues and Lambda functions that execute custom code to handle critical business logic.

- These Lambda functions retrieve the timestamp from videos, then merge the front and rear videos with the number of video frames containing green lights to ultimately match the merged video with car and racing telemetry (for example, screw gun behavior).

The system also includes the use of Amazon Elastic Container Service (Amazon ECS) with multiple microservices, including one that integrates with its ML model in SageMaker AI. Previously, to manually correlate the data, the process took a few minutes per pit stop. Now, the entire process is completed in 60–90 seconds, producing near real-time insights.

The following figure shows the architecture diagram of the solution.

Conclusion

The new pit stop analysis solution allows for a quick and systematic review of every pit stop to identify patterns and refine its processes. After five races in the 2025 season, Scuderia Ferrari HP recorded the fastest pit stop in each race, with a season best of 2 seconds flat in Saudi Arabia for Charles Leclerc. Diligent work coupled with the ML-powered solution more efficiently get drivers back on track faster, focusing on achieving the best end result possible.

To learn more about building, training, and deploying ML models with fully managed infrastructure, see Getting started with Amazon SageMaker AI. For more information about how Ferrari uses AWS services, refer to the following additional resources:

- How AWS Supports Scuderia Ferrari HP to Optimize Formula 1® Power Unit Assembly

- Ferrari Advances Generative AI for Customer Personalization and Production Efficiency

- Ferrari Revolutionizes Automotive Design and Performance with AWS Generative AI Solutions

About the authors

Alessio Ludovici is a Solutions Architect at AWS.

Alessio Ludovici is a Solutions Architect at AWS.

Author: Alessio Ludovici